![[LinuxFocus-icon]](../../common/images/logolftop_319x45.gif) |

LinuxFocus article number 297

http://linuxfocus.org

|

|

|

|

|

![[Photo of the Authors]](../../common/images/KatjaAndGuido.jpg)

by Katja and Guido Socher

<katja/at/linuxfocus.org guido/at/linuxfocus.org>

About the authors:

Katja is the German editor of LinuxFocus. She likes Tux,

computer graphics, film & photography and the sea. Her homepage can be found

here. Guido is a long time Linux fan and he likes Linux because it

gives you choices and freedom. You can choose and develop

solutions according to your needs.

|

Building an autonomous light finder robot

![[Illustration]](../../common/images/article297/robot.jpg)

Abstract:

In this article we describe how to build an autonomous robot with a

microcontroller that will always try to walk to the brightest spot.

_________________ _________________ _________________

|

Introduction

Two years ago we presented a "Linux-controlled walking

robot" in LinuxFocus.

It was very special in its design as it walked on legs and had

no conventional motors. This was a very interesting aspect of

this robot, however it was very slow, needed a lot of current

and required a lot of special parts and skills to build it.

The design of our new robot is very different. It is cheap

and you will be able to build it from parts that are available

almost everywhere around the world. It is an autonomous robot controlled

by an AVR microcontroller. As an autonomous robot (not controlled

by a person) we programmed it to run towards the brightest spot in the room.

The mechanics

![[conrad motor]](../../common/images/article297/297_conrad.jpg)

The small gear motor from conrad

|

![[servo motor]](../../common/images/article297/297_servo.jpg)

A standard servo modified to work as a motor. This is probably the best

solution but we had this idea only after the robot was already built.

|

The robot has only 2 wheels which are driven by 2 independent motors. The

third wheel is a ping-pong ball. This enables the robot to turn on

the spot. We have used rubber wheels from toys but you don't have

to dismantle yours too. The top of a marmalade jar with a rubber band

around also makes for a very nice wheel.

For an autonomous robot it is obviously important that it can

operate from batteries. Since the microcontroller runs with 4.5V the

motors also must work with 3-4.5V. They must also not take too much

current otherwise the batteries and the control circuit will get too big and

heavy. For this design we use an integrated motor driver chip, called l293d.

The l293d motor driver chip can drive peak loads up to 0.5A. The

motors should therefore need less than 0.5A under worst conditions.

We used 2 small gear-box motors from Conrad (www.conrad.de, part

number: 242802) but you can also use any other small motor with

a gear-box. In fact we think now that the best solution would have been

to use standard Servo Motors as used for the remote control of small

boats, cars or planes.

Normally these Servo Motors can turn only a certain angle

but you can open the gear box of the Servo, take out the stopper,

remove the potentiometer and the electronic. It's a perfect small but

strong motor and Servos are easy to get.

![[motor on wooden board 1]](../../common/images/article297/297_mecanics1.jpg)

To build the robot mount the motors under a small wooden board (12cm x 9cm)

and position them almost in the middle such that most of the load will

be on the two axis. The third wheel, the ping pong ball, must take

only a small fraction of the weight of the robot to ensure that it can

slide nicely in its "bearing" (see pictures).

![[motor on wooden board 1]](../../common/images/article297/297_mecanics2.jpg)

The bearing for the ping pong ball is the top of a small plastic bottle which happened to have

exactly the

right size.

![[pill box]](../../common/images/article297/297_mecanics3.jpg)

For the operation of the robot we have used 3 AAA batteries. Position

the battery holders as shown below. The batteries are quite heavy so

take care that most of the load is on the wheels and only a little bit

on the ping pong ball. You can place a switch to power on/off the robot

somewhere on the side.

![[position of the batteries]](../../common/images/article297/batteries.gif)

Sensors

We give our robot 2 types of sensors:

- touch sensors: this way the robot knows if it has hit an object

- light sensors: for the robot to find the brightest spot

in the room

The touch sensors are simple switches made out of steel wire. We bend

them as shown in the picture below:

![[steel wire]](../../common/images/article297/steelwire.jpg)

There are 4 touch sensors mounted with a screw on the corners of the

wooden board.

When the robot hits an object then the steel wire (2, see picture below) touches the

second wire on the board (3) and this closes the electrical connection

between steel wire and wire on the wooden board.

To prevent that the steel wire bends off when the ping pong ball is

not in its bearing we have added a small wooden post (1) under the board. This

post must be about 5 mm above ground when the ping pong ball is in the

bearing.

The steel wire should end about 5-7mm above ground.

![[touch sensors]](../../common/images/article297/touchsensor.jpg)

The light sensors are 3 photo resistors. We placed card

board between the photo resistors as shown in

the picture below. This card board creates

shadows on the resistors when the light comes from the side. Only when the

light comes exactly from the top it will provide for an equal amount of light on

all 3 sensors. Comparing the values of the 3 sensors the robot can

decide in which direction to go.

You can solder the 3 photo resistors on a small experimentation board

(those boards with a lot of holes) and fix the whole thing with a single

screw on the robot.

How to connect the sensors and the two motors to the printed circuit board

with the microcontroller will be explained further down. Now that the

mechanical parts are done let's have a look at the "brain" of the robot.

The Circuit

We use an AT90S4433 microcontroller as the "brain" of our robot but

the "brain" can't directly deliver enough power to drive the motors.

This is where the L293D motor driver chip comes into the picture.

This chip contains 4 digital

output amplifier stages with extra protection diodes to protect

against high voltages induced by the coils of a motor. 2 of the output

stages can be used to drive one motor. This way it is possible to

let the motor turn left or right.

We put one motor between output 1 and output 2 and the other between

output 3 and output 4. The enable pins of the chip can be used

to control the speed of the motors when we send pulses of variable length

to the enable pins.

The rest of the circuit is very simple: We use the Atmel AT90S4433

microcontroller again. You know this microcontroller already from previous

LinuxFocus articles. Its analog inputs can be used to measure the light

on the photo resistors and the touch sensors can be connected directly

to the digital input lines as shown below.

More information about the details of the microcontroller can be found

in Guido's March 2002 article: Programming

the AVR Microcontroller with GCC.

The circuit works with 4.5V. Three AAA batteries are therefore enough to

operate the robot.

Now the circuit for our autonomous robot would be ready. However what do

you do if the robot does not work as expected because something is

going wrong in the software? You can't see anything. You don't know

what the values of the light sensors are, you don't know why the robot software

has taken this or that decision. What we need is some kind of output

screen or display to understand what the robot does. The RS232 serial line

is well suited for this purpose. We can print values of variables

and we could even communicate with the robot. We don't want to connect

it all the time but we need it to debug the robot. It therefore makes

sense to put the max232 and other parts needed for the RS232 connection

onto a separate board and connect it only when needed:

The complete Eagle circuit diagrams and board layouts can be downloaded

at the end of the article together with the software for this robot.

We don't describe the board layout here. You can see it in eagle. The circuit board is small

enough

to fit between the batteries.

Below is a drawing where you can see which touch sensor on which side

of the robot is connected to which pin in the circuit diagram.

The drawing also shows how to connect the motors. The polarity of the

motors is chosen such that the robot would move forward (in the

direction of the arrow) if +3V would be connected to the "+"-pin and GND

to the "-"-pin. 1y to 4y are the names of the pins on the l293d.

![[]](../../common/images/article297/robot_connectors.gif)

The Software

We don't want to go into a lot of details here. The main program can

be found in the file linuxrobot.c (download of the software at the

end of the article). The program includes a lot of comments and

should be easy to read for a C programmer. The main loop first checks

the analog values of the photo-resistors by running the

Microcontroller's internal analog to digital converter in

single shot conversion mode 3 times. After that the touch sensors

are checked. If any of these touch sensors is pressed then

they take preference over the light sensors because it

probably hit some obstacle. The robot will turn the motor

a few milliseconds in the opposite direction of the touch sensor which was hit.

If no touch sensor was hit then the photo sensors are compared with

each other. This comparison is done in the function compare_with_tol()

where we compare one value against a mean value of two. To avoid

that we are affected too much by "noise" we say that 2 values are equal

if the difference is less than 5 percent.

Based on the comparison of the photo sensors we can then decide which

motor to turn. Since we have only 2 wheels we can turn the robot on the

spot by turning one of the wheels faster or even

turning them in opposite direction. Since the microcontroller repeats

the measurement very fast several times per second the movement of the

robot looks as if it continues even if we stop one motor for a

fraction

of a second in order to turn a bit left or right.

Putting it together

When you assemble the electronics it is always a good idea to test

it in steps. This way you can easily narrow down possible faults.

There are 3 different test programs included in the linuxrobot software

package (download at the end of the article).

The program ledtest causes the 2 LEDs to blink. You load it with

the command "make ledtestload". This will compile the program and load

it to the microcontroller. The 2 LEDs should start to blink immediately

after the program was loaded. When this test is successful you can

be sure that the microcontroller with its oscillator and the connection

to the PC for loading software does work.

Next is the motortest program. This test program implements "an electronic rubber

ball". You load it with the command "make motortestload". The motortest

program checks the touch sensors all the time and if one of them is

hit then the robot moves away from the sensor that was hit. If you hit

the robot with your hand on one side then it will bounce back. Put

your second hand behind the robot and it will bounce back and forth

between your 2 hands like a rubber ball. If the robot passes this

test then everything except the light sensors and the RS232 connection

is tested.

The final test program is called adctest (compile and load with

make adctestload). The program tests the RS232 connection which

is there to debug the robot and it tests the ADC (analog to

digital converter) with the 3 photo resistors.

Load the program into the microcontroller and then connect the

adapter for the RS232 connection to your PC. After that run

the following 3 commands in a shell:

make ttydevinit

./ttydevinit /dev/ttyS0

cat /dev/ttyS0

The robot should periodically print the values of the light

intensity it has measured with the photo sensors.

When all the tests are passed you can load the final program

into the robot with "make load".

The best playground for the first tests is a room with

just a single lamp in the middle. The robot should just run

straight in the direction of the lamp and stop there.

It is quite fun to see how it turns around if you put it on

the ground with its back facing to the light source or how it

avoids shades.

Problems and improvements

We started this robot as a little experiment. It was

good fun to build an autonomous robot which can make decisions

on its own and does not need any data connection to a PC.

The program included in the linuxrobot package which you can

download further down in the article is still small and simple

but does what we wanted: The robot runs to the brightest spot.

We would like to mention a few things that could be used as a starting point

for further development:

- The touch sensors are only checked in rather large intervals (few ms)

which limits the responsiveness of the robot. They should be checked

more often.

- If one of the touch sensors was hit then this takes priority over

all other things and the robot moves for a few hundred milliseconds

in the opposite direction. If a different sensor hits during this time

then this is currently ignored.

- The sensitivity of the photo resistors decreases in poor light

conditions.

This can lead to the effect that the difference measured

between the sensors is below the threshold which is hardcoded

in the program (5%) and the robot thinks that all sensors get equal amount of

light. The light values that come out of the ADC could be adjusted

by a non linear filter curve to compensate this effect.

At the moment the linuxrobot program is small and simple so you should be able to understand

it and maybe develop it further. It needs only 50% of

the memory of the 4433 microcontroller so you can still add a lot

of things.

The good thing about this robot is that the hardware is somehow generic:

It's basically 2 motors and some sensors attached to a microcontroller.

All the logic is implemented in the software. That means by changing the

software you can change almost everything as you like.

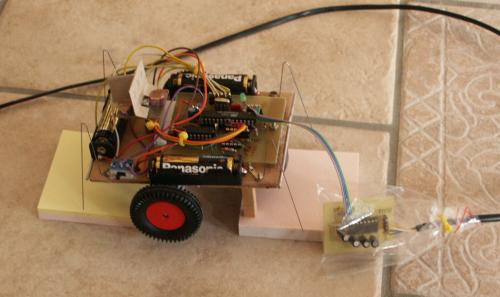

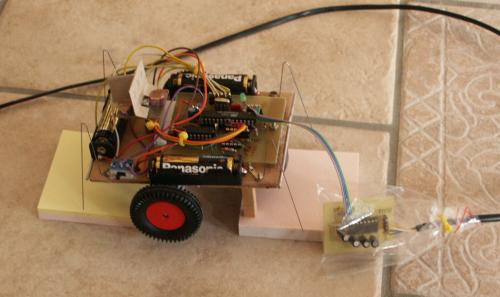

Here is a picture of the robot in test position. We put some post-it paper

block under it so it does not run away. The rs232 line is connected

for debug purposes:

... and the final robot searching for light....:

References

2005-01-14, generated by lfparser_pdf version 2.51

![[Photo of the Authors]](../../common/images/KatjaAndGuido.jpg)

![[Illustration]](../../common/images/article297/robot.jpg)

![[conrad motor]](../../common/images/article297/297_conrad.jpg)

![[servo motor]](../../common/images/article297/297_servo.jpg)

![[motor on wooden board 1]](../../common/images/article297/297_mecanics1.jpg)

![[motor on wooden board 1]](../../common/images/article297/297_mecanics2.jpg)

![[pill box]](../../common/images/article297/297_mecanics3.jpg)

![[position of the batteries]](../../common/images/article297/batteries.gif)

![[steel wire]](../../common/images/article297/steelwire.jpg)

![[touch sensors]](../../common/images/article297/touchsensor.jpg)

![[photo sensors]](../../common/images/article297/lightsensors.jpg)

![[position of the photo sensors]](../../common/images/article297/sensors.gif)

![[]](../../common/images/article297/robot_connectors.gif)